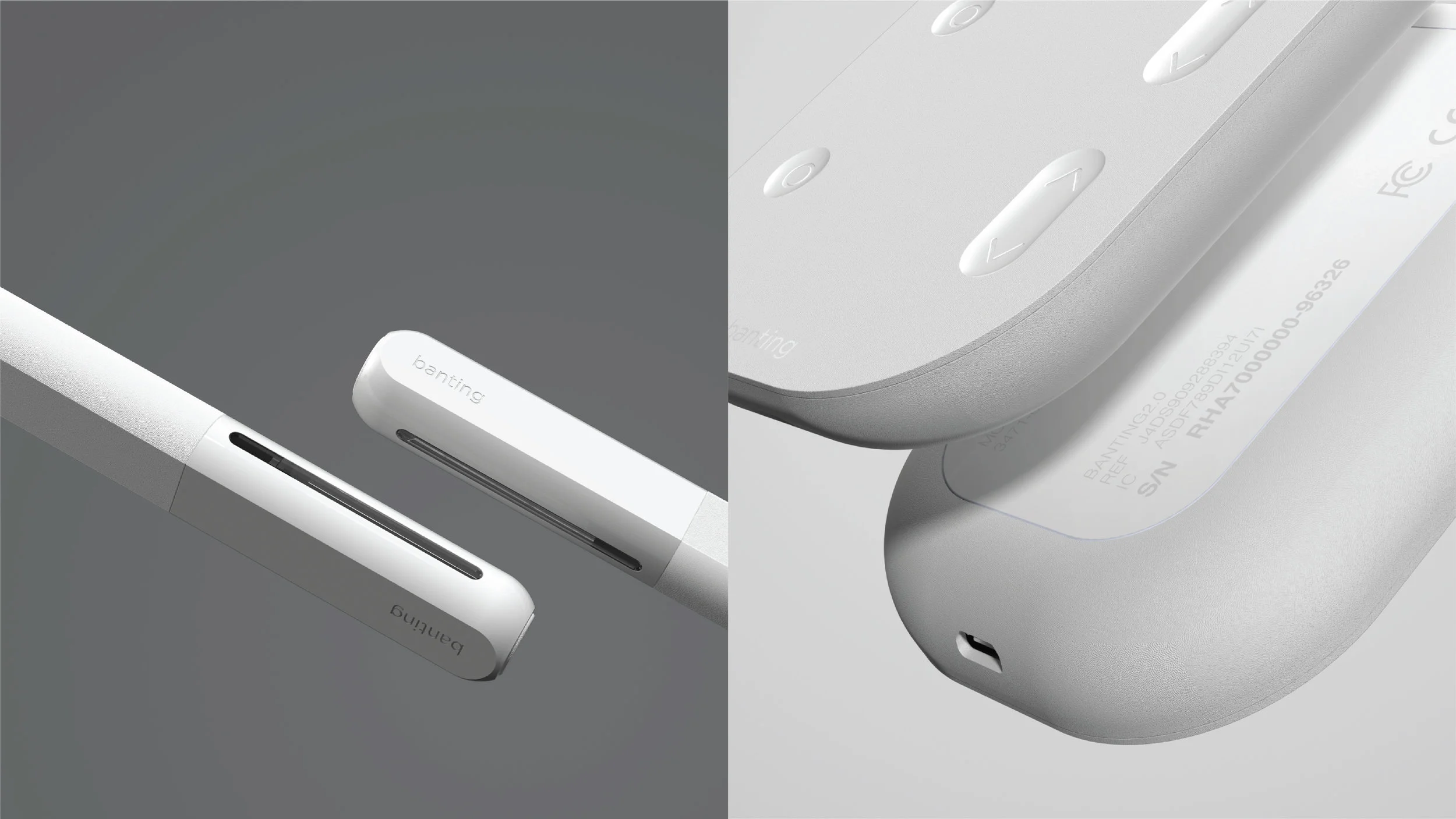

Paying Homage to Dr. Banting

Dr. Fredrick Banting and his colleagues Dr. Best and Dr. Collip were the first people to discover that insulin deficiency was the root cause of diabetes. The three doctors selflessly gave their patents for the first synthetic insulin to the University of Toronto so that it would not fall into the hands of large pharmaceutical companies who could then overcharge and delay production of the lifesaving drug. Nearly 100 years after their discovery, insulin is still out of reach of many in the developing world due largely to the greed of the same large pharmaceutical companies which Banting, Best and Collip fought to deter. Similarly, the goal of this project is to re-democratize lifesaving diabetes technology by undercutting Big Pharma and the proprietary restrictions they have set in place.